Saddle-stitch booklets are gaining popularity in Australia for their affordability and professional appeal. This method involves folding sheets in half and stapling them along the crease, making it an efficient printing process that provides a professional appearance for multi-page printed materials. It’s perfect for booklets with 8 to 76 pages. This binding style ensures your materials open flat, making it great for brochures, catalogues, and marketing materials.

At MVP Print, we’re experts in high-quality saddle stitch booklet printing. Our process includes collation, folding, stapling, and trimming. This results in a clean, polished finish. Whether you need a small batch or a large print run, our team and advanced equipment guarantee top-notch results.

Understanding Saddle Stitch Booklet Basics

Saddle stitched booklets are a cost-effective and popular choice for various publications. They involve folding pages in half and securing them with wire staples along the spine. This method creates a neat, professional finish. It’s ideal for shorter print runs, appealing to both businesses and individuals.

What is Saddle Stitching?

Saddle stitching is a popular binding method used in booklet printing, where wire staples are inserted through the spine of the booklet to hold the pages together. This process involves folding the sheets of paper in half and stapling them along the crease, creating a professional-looking booklet that opens flat. Saddle stitching is a cost-effective and efficient way to produce booklets, brochures, and other multi-page printed materials. This binding method is particularly favored for its simplicity and the polished finish it provides, making it a go-to choice for many print projects.

What Makes Saddle Stitching Different

Saddle stitching stands out for its simplicity and efficiency. Unlike perfect binding, it uses wire staples to bind pages. This approach makes it a budget-friendly, quick option for publications up to 60-70 pages.

The Binding Process Explained

The printed pages and cover are folded in half and stacked together, creating a booklet-like structure.

Wire staples are then inserted through the crease, securing the pages along the spine.

This binding process is suitable for both short and long print runs, making it a versatile option.

Types of Paper and Materials Used

Saddle stitched booklets can be made from various paper types, including glossy, matte, and uncoated paper stocks. The cover can be the same as the inner pages (self-cover) or a thicker, coated stock for durability and appeal. The choice of materials significantly affects the booklet’s look and feel.

Benefits of Choosing Saddle Stitch Binding

Saddle stitch binding is a top choice for many print projects. It’s known for being cost-effective, offering a professional finish, and being highly versatile. This binding method provides great value and flexibility for various needs.

Cost-Effectiveness and Quick Turnaround

Saddle stitch binding is very affordable, needing only basic materials and a simple setup. This means big savings, perfect for projects with tight budgets. Plus, its quick production process allows for fast delivery, often within a day at MVP Print.

Professional Finish and Durability

Despite being budget-friendly, saddle stitch binding gives a sleek, professional look. It’s also durable, making sure your printed materials last through frequent use and handling.

Versatility in Design and Application

Saddle stitch binding is incredibly adaptable, fitting custom sizes and designs easily. It’s great for event programs, product catalogues, and marketing materials. Its flexibility makes it suitable for both small and large print runs, serving businesses of all sizes.

Applications of Saddle Stitch Booklets

Saddle stitch booklets have a wide range of applications, making them a versatile choice for various needs. They are commonly used for event programs and schedules, providing attendees with a clear and organized guide. Product catalogs and brochures benefit from this binding method, offering a sleek presentation of products and services. Instruction manuals and guides are also well-suited for saddle stitching, ensuring durability and ease of use. Marketing materials and promotional booklets can effectively convey messages with a professional touch. Additionally, educational materials and workbooks, as well as menus and restaurant guides, often utilize saddle stitch booklets for their practicality and aesthetic appeal. Whether for businesses, organizations, or individuals, saddle stitch booklets deliver high-quality, professionally bound materials in both large and small quantities.

Page Count and Size Limitations

Page count and size are key factors in the quality and functionality of saddle stitch booklets. These booklets are best suited for 8 to 76 pages. However, as pages increase, the booklet’s thickness can hinder its ability to lie flat. For higher page counts, perfect binding might be a better option.

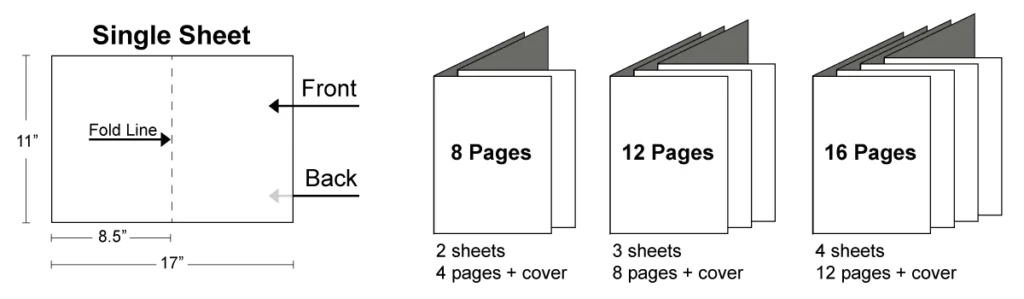

Saddle stitch booklets need page counts in multiples of four. This ensures the pages fold and stitch together seamlessly. If the page count doesn’t fit, adding blank pages to the covers can solve the issue.

The size of saddle stitch booklets is influenced by paper thickness and printing equipment. Paper weights between 60 to 100 lb (90 to 150 gsm) are ideal. Thicker papers, around 80 to 100 lb (120 to 150 gsm), add stability and a premium feel.

The maximum page count for saddle-stitched booklets is theoretically 120 pages. However, it’s recommended to keep it under 60 pages. This ensures the booklet lies flat and looks professional when opened.

In conclusion, understanding page count and size limitations is essential for creating high-quality saddle stitch booklets. By following these guidelines, you can produce durable, visually appealing booklets that meet your needs.

Professional Tips for Creating Quality Saddle Stitched Publications

Creating engaging saddle stitch booklets demands attention to detail. It’s crucial to maintain consistent margins and balance between text and images. High-quality images are essential to prevent pixelation. Always proofread your content before printing to ensure accuracy.

Design Considerations for Best Results

When designing saddle stitch booklets, remember to have a page count that’s a multiple of four. Each folded sheet adds four pages. Ensure you have enough bleed areas around the edges for a clean finish. Proper imposition is key for efficient printing and binding, taking into account the folding and stitching.

Paper Selection Guidelines

Paper choice should enhance your design and purpose. For brochures and informational booklets, lightweight paper (70-100 GSM) is best. Standard paper (100-120 GSM) works well for a broad range of publications. Heavyweight paper (120-200 GSM) offers a premium feel and durability. Cover stock (200+ GSM) is ideal for the cover pages.

Common Printing Specifications

Cover printed options, such as those used for saddle-stitched and hard cover books, require careful consideration of paper weight and types for the covers compared to the internal pages. Proper alignment during folding and stapling is vital to avoid issues like misalignment and uneven stapling. Collaborate with experienced printers like MVP Print for top-notch results. Remember to consider bleed and trim areas in your design. Standard sizes are cost-effective, but custom sizes can meet specific needs.

Finishing Options

Saddle stitch booklets can be finished in a variety of ways to enhance their appearance and durability. One popular option is the self-cover, where the cover is printed on the same paper stock as the internal pages, providing a uniform look. For a more robust feel, a hard cover can be used, printed on a heavier paper stock than the internal pages. Laminating the cover with a clear plastic coating adds an extra layer of protection against wear and tear. Varnishing offers a glossy or matte finish, enhancing the booklet’s visual appeal. Die-cutting allows for custom shapes or designs on the cover, adding a unique touch. Foil stamping applies metallic foil to the cover, creating decorative designs or logos that stand out. These finishing options not only make your saddle stitch booklet more attractive but also give it a professional, high-quality appearance that can leave a lasting impression.

Conclusion

MVP Print excels in saddle stitch booklet printing, offering a budget-friendly and adaptable solution for various printed materials. This method is perfect for creating professional booklets, from marketing materials to event guides. It ensures quick production and a wide array of customisation options.

Saddle stitch booklets are best for page counts under 64, yet they remain a favourite for their affordability and sleek finish. By focusing on design, paper quality, and collaborating with MVP Print, businesses can craft lasting, impactful publications. These stand out in a crowded market.

Australian companies can enhance their printed materials’ quality and message impact through saddle stitch booklet printing. Whether you need a few brochures or a larger booklet, MVP Print’s expertise ensures your products are both professional and affordable.