Creating a Saddle Stitch Bound Book layout demands precision and thorough planning, especially when considering various binding methods. By avoiding common pitfalls, you can achieve a professional and flawless outcome. This article will delve into the essential mistakes to sidestep and offer practical advice for producing a top-notch publication.

Steering clear of layout errors is vital for a refined, professional saddle stitched book. It’s crucial to plan meticulously and focus on every detail. Grasping the basics of saddle stitching and the printed page construction is fundamental. Ensuring optimal page counts and avoiding pagination mistakes are crucial for a smooth reading experience. Choosing the right paper stock and considering margins and binding allowances are also critical.

Understanding Saddle Stitch Bound Binding with Wire Staples

Saddle stitching is a simple and cost-effective booklet binding method. It’s a popular choice for various print projects. This binding technique involves folding sheets of paper in half and stapling them along the folded edge. This creates a spine.

The folded sheets are nested inside each other, forming the pages of the booklet. The cover, made from a heavier paper stock, is wrapped around the booklet. It’s stitched together with the pages using wire staples.

The Basics of Saddle Stitch Bound Books

Saddle-stitched binding suits projects with a number of pages ranging from 4 to 64, following the “rule of four”. However, books over 64 pages may not lay flat. This affects their usability and visual appeal.

Advantages of Saddle Stitch Binding

The saddle stitch binding method is chosen for several reasons. It’s a cost-effective option, fitting both large and small print runs. The construction process is simple, ensuring quicker turnaround times.

This is especially beneficial for urgent projects. Saddle stitched booklet binding is versatile, accommodating a wide range of applications. It’s ideal for brochures, catalogs, event programs, and newsletters.

Lastly, saddle stitching offers a clean and professional look. These finished booklets lie flat when open, making content easy to view. The durability of wire staples keeps the booklets intact, even with frequent use.

Preparing Your Document for Saddle Stitching

When preparing your document for saddle stitching, it’s essential to consider the page size and orientation to ensure a professional-looking finish.

Page Size and Orientation of Saddle Stitch Bound Books

The page size and orientation of your document will determine the final size of your saddle-stitched booklet. Typically, saddle-stitched booklets are printed in portrait orientation, with the pages folded in half to create a compact and easy-to-handle format. The standard page sizes for saddle-stitched booklets are 210x297mm,148x 210mm, and 105x148mm. However, you can choose a custom page size to suit your specific needs.

To ensure that your document is prepared correctly for saddle stitching, make sure to set the page size and orientation in your design software. You should also consider the bleed area, which is the area around the edges of the page that will be trimmed off during the binding process. A minimum bleed of 3mm is recommended to ensure that your design is not cut off during trimming.

Crucial Layout Considerations for Saddle Stitch Bound Documents

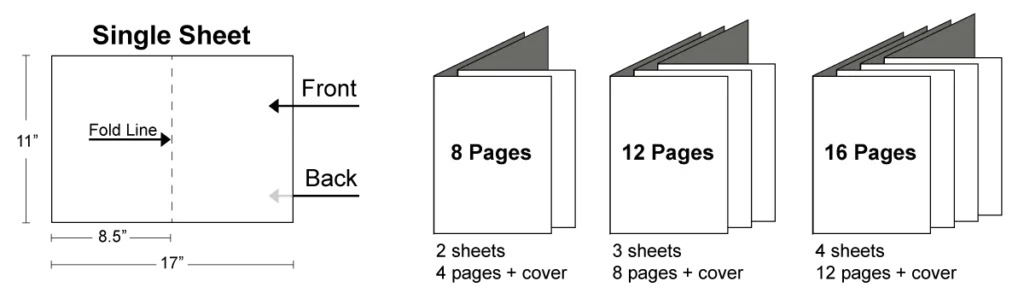

Designing a saddle stitched booklet requires understanding the role of multiples of 4 in page layout. Each folded sheet creates four printed pages in a saddle stitched booklet. Adhering to multiples of 4 ensures pages align properly, avoiding blank or missing pages. Incorrect page counts can lead to misalignment and a less professional look, making this aspect crucial.

The Importance of Multiples of Four in Page Layout and Page Count

Statistics reveal that 100% of saddle stitched booklets follow multiples of 4 in their layout. This approach guarantees a seamless and consistent presentation, eliminating gaps or discrepancies. By aligning your page count with these multiples, you achieve a professional-looking booklet that adheres to industry standards.

Avoiding Pagination Errors

Page creep is a common issue in saddle stitched books with high page counts. It occurs when pages shift as the book is folded and stapled. The innermost pages are pushed towards the spine, causing outer pages to shift outward. To combat page creep, adjust your layout to include extra margin space near the spine. This ensures no critical information or design elements are lost during binding.

Common pagination errors in saddle-stitched booklets include incorrect page numbering, missing or duplicate pages, and improper placement of headers and footers. Being aware of these issues helps maintain a consistent and balanced layout in your saddle stitched book, even with higher page counts.

Design Considerations for Saddle Stitch Bound Booklets

When designing a saddle-stitched booklet, there are several factors to consider to ensure a professional-looking finish.

Cover Design and Layout for Saddle Stitch Bound Books

The cover of your saddle-stitched booklet is the first thing that your audience will see, so it’s essential to make a good impression. The cover should be designed to be visually appealing, with a clear and concise title and any relevant graphics or images. The cover should also be designed to be functional, with a clear and easy-to-read layout.

When designing the cover, consider the following factors:

- The cover should be designed to be slightly larger than the interior pages to allow for trimming and folding.

- The cover should be designed to be visually appealing, with a clear and concise title and any relevant graphics or images.

- The cover should be designed to be functional, with a clear and easy-to-read layout.

Choosing the Right Paper Stock for Saddle Stitch Bound Documents

When crafting high-quality saddle stitched booklets, the choice of paper stock is paramount. The weight and thickness of the paper are key factors to consider. Paper weight indicates its density, with heavier paper being more durable for saddle stitching. For booklets, a paper weight between 90 to 150 gsm is recommended.

The thickness of the paper also plays a significant role. Thicker paper enhances stability and gives your booklet a premium feel. For the interior pages, a thickness of 120 to 150 gsm is typically advised.

For the cover of your booklet, you have two choices: self-cover and plus cover. A self-cover uses the same paper as the inner pages, ideal for smaller booklets for a unified look. A plus cover, however, employs a thicker, more robust cover stock. This is perfect for larger booklets or when you desire a distinct cover.

| Paper Stock Considerations | Recommendation |

|---|---|

| Paper Weight for Interior Pages | 90 to 150 gsm |

| Paper Thickness for Interior Pages | 120 to 150 gsm |

| Cover Options | Self-cover (same paper as interior)Plus cover (thicker, more robust paper) |

Selecting the right paper stock for your saddle stitched booklets ensures a professional finish, durability, and a premium feel. This elevates the overall impact of your printed materials.

Finishing Options

There are several finishing options available for saddle-stitched booklets, including folding, trimming, and binding. The finishing options you choose will depend on the specific needs of your project.

- Folding: Saddle-stitched booklets can be folded in half to create a compact and easy-to-handle format.

- Trimming: The pages of your saddle-stitched booklet can be trimmed to size to create a clean and professional finish.

- Binding: Saddle-stitched booklets can be bound using wire staples or a perfect binding method.

By considering these design factors and finishing options, you can create a professional-looking saddle-stitched booklet that meets your specific needs and impresses your audience.

Saddle Stitch Bound: Margin Consistency and Binding Adjustments

Creating professional saddle stitched booklets requires consistent margins and accounting for binding edge and spine thickness. These elements are key to the design, functionality, and reader experience of your printed material.

Maintaining Consistent Margins Throughout

Consistent margins are vital for a polished, cohesive saddle stitched book. They ensure a harmonious visual flow and maintain a professional appearance. Consistent margins also enhance the reader’s comfort, preventing crucial information from being lost or obscured during binding.

Adjusting for Binding Edge and Spine Thickness

Binding edge and spine thickness can affect content visibility and readability. It’s crucial to account for these factors in your design to prevent information loss. By ensuring enough space near the binding edge and adjusting the layout for cover stock thickness, all content remains visible and readable post-binding.

| Paper Type | GSM Range | Recommended Use |

|---|---|---|

| Lightweight paper | 70-100 GSM | Ideal for brochures and informational booklets |

| Standard paper | 100-120 GSM | Great for a wide range of saddle stitched books |

| Heavyweight paper | 120-200 GSM | Provides a premium feel and durability |

| Cover stock | 200+ GSM | Perfect for cover printed projects |

“Professionals invested half-a-million dollars to upgrade their bindery equipment to enhance efficiency in production and reduce costs due to the elimination of the folding step prior to saddle stitching.”

Conclusion

The creation of saddle stitch bound documents demands attention to detail and careful planning. Understanding the basics of saddle stitching and the significance of page layout is crucial. It helps avoid common mistakes, ensuring your saddle stitched booklets look polished and professional.

Following the Rule of Four in page layout is essential. Adjustments for page creep and consistent margins are also key. This way, you can create saddle stitch books that impress your audience. Whether it’s instruction manuals, marketing materials, or other saddle stitched documents, the outcome will be impactful.

Considering the advantages of saddle stitch binding is vital. Its cost-effectiveness and ability to lay flat are significant benefits. These factors help you choose the most suitable binding option for your printing project. With the right strategy, saddle stitch binding can enhance your publications, making them visually appealing and professional.