In the ever-evolving world of printing and bookbinding, staying ahead of the curve is crucial for both producers and consumers. One such advancement that has revolutionised the way books are bound is the introduction of PUR bound books, the superior form of Perfect Binding. This cutting-edge technique has become synonymous with durability, flexibility, and a level of quality that is far ahead of traditional binding methods. In this article, we delve into the ins and outs of PUR binding, how it is produced, and why it stands out as a superior choice for book finishing.

Key Takeaways:

- PUR binding offers superior durability and flexibility.

- PUR bound books are of higher quality compared to traditional binding methods.

- This modern technique has revolutionized the way books are bound.

- Understanding the advantages of binding types is essential for modern book publishers.

- PUR binding ensures books can withstand wear and tear, providing longevity.

Understanding PUR Binding in Today’s Book Manufacturing

Polyurethane Reactive (PUR) binding is a modern bookbinding method that utilizes a reactive adhesive containing polyurethane. Unlike traditional methods that use hot melt or cold glue, PUR binding offers several distinct advantages.

What is Polyurethane Reactive (PUR) Binding?

PUR binding is a cutting-edge technique that has revolutionized the way books are bound, surpassing traditional binding methods in terms of durability, flexibility, and overall quality. By using a reactive adhesive containing polyurethane, PUR binding forms a strong and long-lasting bond between the book’s pages and cover.

The Process of Creating a PUR Bound Book

The process of creating a Perfect bound book involves several steps. Firstly, the pages are prepared, ensuring they are clean and flat. Then, the PUR adhesive is applied to the spine of the book, ensuring thorough coverage. Finally, the book undergoes a curing process to activate the reactive adhesive and create a durable bond.

Comparing PUR Glue to Traditional Adhesives

When comparing PUR glue to traditional adhesives commonly used in bookbinding, PUR offers superior strength and durability. The polyurethane reactive adhesive forms a bond that is more resistant to wear and tear, ensuring the longevity of the book. Additionally, PUR-bound books have enhanced flexibility, allowing for a seamless reading experience.

Why PUR Binding Outshines Traditional Perfect Binding

PUR binding offers significant advantages over traditional perfect binding methods, making it the preferred choice for modern book publishing. The chemical reaction that occurs during the curing process of PUR binding creates a stronger and more durable bond compared to traditional perfect binding. This enhanced bond ensures that books are more resistant to wear and tear, increasing their longevity and durability.

One of the standout features of PUR binding is its ability to offer enhanced lay-flat properties. Unlike traditional perfect binding, PUR-bound books open and lay flat without resistance, providing a seamless reading experience and ease of use. This feature is particularly desirable for various book types, such as cookbooks, design portfolios, and other publications where a lay-flat format is essential.

In addition to its durability and lay-flat properties, PUR binding also offers flexibility in design. Its superior bond strength allows for the utilization of a wide range of paper stocks, including various coated and uncoated options. Publishers and designers can have the creative freedom to experiment with different paper types, textures, and finishes, while still maintaining the high-quality binding that PUR offers.

Overall, the advantages of PUR binding over traditional perfect binding are clear. Its stronger and more durable bond, enhanced lay-flat properties, and flexibility in design make it the ideal choice for modern book publishing. Publishers and consumers can rely on PUR binding to deliver books that not only withstand the test of time but also provide a superior reading experience.

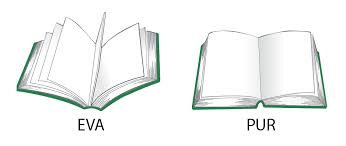

Advantages of PUR Binding Over EVA Adhesive

When comparing PUR binding to EVA (Ethylene Vinyl Acetate EVA) adhesive, PUR binding offers several notable advantages. These advantages include increased binding strength and durability, resistance to temperature extremes, and enhanced lay-flat properties.

Increased Binding Strength and Durability

PUR binding provides exceptional binding strength and durability, surpassing books bound with EVA adhesive. In page pull out tests, PUR-bound books often exhibit up to 50% stronger results compared to books using EVA glue. This applies to both the Hard Cover and Soft Cover Book Options.

This superior strength ensures that PUR-bound books can withstand frequent use and maintain their structural integrity over time.

Less Susceptible to Temperature Extremes

One of the key advantages of PUR binding is its resilience in temperature extremes. Unlike EVA adhesive, which can soften or become brittle in extreme hot or cold conditions, PUR-bound books remain stable and unaffected by temperature fluctuations. This makes PUR binding an ideal choice for having a book bound that need to withstand varying environmental conditions.

Enhanced Lay-Flat Properties

These books offer enhanced lay-flat properties, providing a seamless reading experience and ease of use. The flexible nature of PUR adhesive allows the pages to open flat, making it easier to read and reference the inner pages without the book closing shut. From cookbooks to design portfolios, books bound with PUR glue offer optimal functionality and usability.

PUR Binding versus EVA Adhesive Binding Strength and Durability

PUR

✓ 50% stronger results in page pull tests compared to EVA glue

✓ Stable in hot and cold conditions

✓ Enhanced lay-flat capabilities for a seamless reading experience

EVA

✓ Less durable and may exhibit weaker binding strength Resistance to Temperature Extremes

✓ Can soften or become brittle in extreme temperatures Lay-Flat Properties ✓ Enhanced lay-flat capabilities for a seamless reading experience

✓ May not lay flat when opened, resulting in inconvenience

The Role of PUR Adhesive in Longevity and Usability

The use of PUR adhesive in book binding plays a vital role in ensuring the longevity and usability of books. During the curing process, a chemical reaction occurs between the adhesive and the paper fibers, creating a strong and durable bond. This bond enables books to withstand frequent use and maintain their structural integrity over time.

One of the key advantages of this renowned adhesive is its flexibility, which allows books to open flat. This enhances the usability of the books, as readers can easily flip through the pages without worrying about the book snapping shut or damaging the spine. The seamless reading experience provided by PUR binding enhances user satisfaction and convenience.

PUR Binding: The Preferred Method for Various Paper Stocks

PUR binding is a versatile and highly preferred method for binding various types of paper stocks. Whether you’re working with glossy or matte paper, PUR binding offers the flexibility and compatibility to accommodate different paper types while maintaining durability and quality.

Flexibility with Different Types of Paper

One of the key advantages of PUR binding is its flexibility with different types of paper. Whether you’re using coated or uncoated paper, lightweight or heavyweight, PUR binding ensures a secure and lasting bond between the pages. This flexibility allows for creative freedom in design, making it ideal for a wide range of book projects.

PUR Binding for High-Quality Recycled Paper

PUR binding is also a perfect choice for high-quality recycled paper. As more publishers and printers embrace sustainable practices, PUR binding offers a solution that doesn’t compromise on book quality. It provides a strong and durable binding for recycled paper, ensuring that the final product meets both environmental and quality standards.

Eco-Friendly Aspects of PUR Binding

PUR binding is not only a superior bookbinding method but also an eco-friendly choice that aligns with sustainability and environmentally conscious practices. Compared to traditional binding methods, the PUR binding process itself is more environmentally friendly, making it a preferred choice for publishers who are committed to minimizing their environmental impact.

Companies like MVP Print embrace these eco-friendly practices and offer this advanced binding method as part of their commitment to delivering high-quality printing while contributing to a greener future.

Key Elements of PUR Binding Machinery and Equipment

To achieve strong and durable book bindings with PUR binding, specialized machinery and equipment are essential. These key elements ensure the precise application of the PUR adhesive, resulting in high-quality finished products. Additionally, proper maintenance and regular cleaning of PUR binding machines are crucial for optimal performance and longevity.

Specialized Equipment for Applying PUR Adhesive

To apply the PUR adhesive accurately and efficiently, specialized equipment is required. This includes PUR glue applicators, which allow for precise control and even distribution of the adhesive along the spine of the book. These applicators are designed to handle the specific characteristics of PUR adhesive, ensuring a strong bond between the pages. Using specialized equipment for applying PUR adhesive guarantees consistent and reliable results.

Maintenance and Cleaning of PUR Binding Machines

Maintenance and cleaning play a vital role in the performance and lifespan of PUR binding machines. Regular maintenance, such as lubricating moving parts and replacing worn components, helps prevent malfunctions and ensures smooth operation. Cleaning the machines regularly removes any residual adhesive or debris that may accumulate during the binding process. By adhering to proper maintenance and cleaning procedures, publishers and printers can prolong the lifespan of their PUR binding machines and minimize downtime.

Creative Possibilities with PUR Perfect Binding

PUR perfect binding offers a world of creative possibilities for book design and customization. With its flexibility and durability, PUR binding is suitable for various book types, allowing for the creation of unique designs and personalized touches. Whether you’re working on a glossy coffee table book, a children’s book with vibrant illustrations, or a special edition novel, PUR perfect binding can bring your creative visions to life.

Imagine the possibilities of a customized cover design, embossed with intricate details or featuring a striking artwork that captures the essence of the book. With PUR perfect binding, the cover can be tailored to match the content and style of your publication, making it visually appealing and enticing to potential readers.

Not only does PUR perfect binding enable you to design eye-catching covers, but it also allows for impressive interior layouts. You can have full-color illustrations spill seamlessly across pages, creating a visually stunning reading experience. By utilizing the lay-flat properties of PUR binding, you can ensure that each page lies flat, enhancing the usability and enjoyment of your book.

The customization options with PUR perfect binding go beyond the layout and cover design. You can experiment with different paper textures and weights to add a tactile element to your book. Consider using specialty papers like parchment or handmade paper to evoke a sense of craftsmanship and luxury.

Furthermore, PUR perfect binding provides the flexibility to incorporate additional features like fold-outs, pockets, or tip-ins. Integrate interactive elements into your book, such as QR codes, augmented reality content, or embedded videos, to create an immersive reading experience.

No matter the genre or purpose of your book, PUR perfect binding offers endless opportunities for creativity and personalization. Let your imagination run wild and bring your unique vision to fruition with PUR perfect binding.

Impact of PUR: Considerations for Publishers and Printers

The impact of PUR binding is significant for both publishers and printers. PUR binding offers better structural integrity, making it a preferred choice for books that will be frequently used or subjected to demanding conditions. Additionally, opting for PUR binding can elevate the quality of high-end publishing projects, ensuring that the final product exceeds expectations in terms of durability and aesthetics.

Publishers looking for print Novels, Children’s books, Coffee Table Books – anything with a printed spine’s shape, are making the change to PUR.

Better Structural Integrity for Frequent Usage

PUR binding provides superior structural integrity compared to traditional binding methods. The reactive adhesive containing polyurethane forms a strong and durable bond, ensuring that the pages remain securely bound even with frequent use. Books that undergo extensive handling, such as textbooks, manuals, or reference guides, greatly benefit from PUR binding’s ability to withstand wear and tear.

Opting for PUR Binding in High-End Publishing

High-end publishing projects require meticulous attention to detail and exceptional quality. PUR binding meets these criteria by offering a luxurious finish with enhanced durability. Whether it is a high-quality art book, a limited edition collector’s item, or a premium coffee table book, opting for PUR binding elevates the final product to a level of sophistication and durability that traditional binding methods simply cannot match.

Advantages of PUR Binding Considerations for Publishers and Printers

Better structural integrity

Ensures books can withstand frequent usage and demanding conditions

Elevates high-end publishing

Enhances the quality and durability of premium publications

The Influence of PUR Binding on the Book’s Aesthetics

PUR binding plays a significant role in enhancing the aesthetics of a book. The clean and precise edges achieved through PUR binding contribute to a visually appealing finished product. The seamless and professional look of PUR bound books adds to their overall visual appeal, making them stand out on the bookshelf.

One of the key visual advantages of PUR binding is its superior lay-flat characteristics. The flexibility of the PUR adhesive allows the book to open flat, ensuring a seamless and immersive reading experience. Whether it’s a novel, a photography book, or a design portfolio, the lay-flat feature enhances the book’s overall visual impact.

The durability and flexibility of PUR binding provide publishers and designers with the opportunity to create books with a polished and high-end appearance. Whether it’s a hardcover novel or a coffee table book, the aesthetics of PUR binding complement the content and create a visually stunning final product. Publishers can leverage the clean edges and lay-flat capabilities of PUR binding to showcase their creativity and attention to detail.

By choosing PUR binding, publishers and designers can elevate the visual appeal of their books, creating a lasting impression on readers. The aesthetics of a book play a crucial role in attracting readers’ attention and encouraging them to pick up the book. With PUR binding, publishers can ensure that their books not only captivate readers with their content but also entice them with their visual allure.

Choosing Between PUR Binding and Other Binding Methods

When it comes to bookbinding, choosing the right method is crucial for the success of your project. Perfect binding (PUR) is a popular option that offers several advantages over other binding methods. In this section, we will explore when to choose PUR binding for your project and compare it to other commonly used binding methods like saddle stitching, wire binding, spiral, and section sewn.

When to Choose PUR Binding for Your Project

There are several factors to consider when deciding whether PUR binding is the right choice for your project:

- The type of project: Perfect binding (PUR) is suitable for a wide range of book types, including softcover books, catalogs, manuals, and more.

- Desired book aesthetics: If you want a clean and professional look with precise edges, PUR binding is an excellent choice. Works wit virtually any Ink or paper stock.

- Durability: If durability is a priority, especially for books that will be frequently used or subjected to challenging conditions, PUR binding offers superior strength and longevity.

- Budget: While PUR binding may have a slightly higher upfront cost compared to some other methods, its durability and quality make it a cost-effective option in the long run.

Comparing PUR to Saddle Stitching, Spiral, and Section Sewn

Let’s take a closer look at how PUR binding compares to other commonly used binding methods:

Binding Method Strength and Durability

Lay-Flat Properties Suitability for Different Paper Stocks

PUR Binding Provides a strong and durable bond, ensuring the book withstands frequent use and challenging conditions.

Offers enhanced lay-flat properties, allowing for a seamless reading experience. Accommodates different types of paper, including high-quality recycled paper.

Saddle Stitching is Suitable for thinner booklets and magazines but may not be as durable as PUR binding for thicker books. Does not offer lay-flat properties, which can be a disadvantage for certain book types. Compatible with various paper stocks, but limitations may arise with thicker or heavier papers.

Spiral Binding Provides flexibility and allows the book to lie flat when opened, but may not offer the same level of durability as PUR binding. Offers excellent lay-flat properties, making it ideal for workbooks, notebooks, and manuals. Compatible with most paper stocks, but limitations may arise with thicker or heavier papers.

Section Sewn Offers excellent durability and creates a strong bond, but may not be as flexible as PUR binding. Does not offer lay-flat properties, which can be a drawback for certain book types. Compatible with various paper stocks, including thicker or heavier papers.

As you can see, each binding method has its advantages and considerations. By carefully evaluating your project requirements and the characteristics of each method, you can make an informed decision and choose the binding method that best suits your needs.

PUR Binding – in a Nutshell

PUR binding is a high-quality book-finishing method that offers durability and flexibility. By utilizing a reactive adhesive containing polyurethane, PUR binding creates a strong and durable bond that can withstand frequent use and challenging conditions. This innovative binding technique has become synonymous with high-quality book finishing, providing publishers and printers with a reliable method to produce books that stand the test of time.

Conclusion

In conclusion, Perfect binding has revolutionized the world of book manufacturing. With its numerous benefits, including exceptional durability, flexibility, and high-quality binding, PUR binding has become the preferred choice for publishers and printers.

By utilizing a reactive adhesive containing polyurethane, this binding method creates a strong and long-lasting bond that ensures books can withstand the test of time.

Publishers and printers can rely on PUR binding requirements to deliver books that surpass expectations in terms of durability and aesthetics. The flexibility of PUR-bound books allows for an enhanced reading experience, with pages effortlessly laying flat. This feature is particularly advantageous for cookbooks, design portfolios, and any publication where a lay-flat format is desired.

As technology continues to advance, PUR binding remains at the forefront of book manufacturing. Its ability to combine exceptional durability with flexibility sets it apart from traditional binding methods. If you’re looking for a method that guarantees a superior finish and longevity, choose PUR binding for your next book project.

FAQ

What is Polyurethane Reactive (PUR) Binding?

Polyurethane Reactive (PUR) binding is a modern bookbinding method that uses a reactive adhesive containing polyurethane. This adhesive creates a strong and durable bond during the curing process, resulting in books that are more resistant to wear and tear compared to traditional binding methods.

How is a PUR bound book created?

To create a PUR bound book, the pages are prepared, and the PUR adhesive is applied to the spine. The book then goes through a curing process, during which a chemical reaction occurs between the adhesive and the paper fibers, creating a durable bond.

How does PUR glue compare to traditional adhesives?

PUR glue offers superior strength and durability compared to traditional adhesives used in bookbinding. The curing process of PUR adhesive creates a stronger and more durable bond, making books more resistant to wear and tear.

What are the advantages of PUR binding over traditional perfect binding?

PUR binding offers several advantages over traditional perfect binding. The chemical reaction during the curing process of PUR binding creates a stronger and more durable bond, making the books more resistant to wear and tear. Additionally, PUR-bound books have enhanced lay-flat properties, providing a seamless reading experience.

How does PUR binding compare to EVA adhesive?

PUR binding provides increased binding strength and durability compared to EVA adhesive. Page pull tests often show up to 50% stronger results for books using PUR glue. Additionally, it is less susceptible to temperature extremes and offers enhanced lay-flat properties.

What role does PUR adhesive play in book binding?

PUR adhesive plays a crucial role in ensuring the longevity and usability of a book. The chemical reaction that occurs between the adhesive and the paper fibers during the curing process creates a strong and durable bond, resulting in books that can withstand frequent use and maintain their structural integrity over time.

Can PUR binding accommodate different types of paper?

Yes, it is suitable for various types of paper, including glossy or matte finishes. It offers flexibility in design while maintaining durability and quality. PUR binding is also compatible with high-quality recycled paper, allowing for sustainable publishing practices.

Are there any eco-friendly aspects of PUR binding?

Yes, these books have eco-friendly aspects that align with sustainability and environmentally conscious practices. The PUR binding process itself is more environmentally friendly compared to traditional binding methods, making it a preferred choice for publishers looking to minimize their environmental impact.

What are the key elements of PUR binding machinery and equipment?

The key elements of Perfect Bound machinery and equipment include specialized tools for applying PUR adhesive and procedures for maintenance and cleaning. Specialized equipment ensures precise application of PUR adhesive, resulting in strong and durable book bindings. Regular maintenance and cleaning are essential to maintain optimal performance and prolong the lifespan of the equipment.

What creative possibilities does PUR perfect binding offer?

Perfect binding offers creative possibilities in book design and customization. The flexibility and durability of PUR binding make it suitable for various book types, allowing for unique designs and personalized touches. Whether it’s a glossy coffee table book or a children’s book with vibrant illustrations, PUR perfect binding can bring creative visions to life.

How does PUR binding impact publishers and printers?

PUR books offers better structural integrity, making it a preferred choice for books that will be frequently used or subjected to demanding conditions. Additionally, opting for this superior binding can elevate the quality of high-end publishing projects, ensuring that the final product exceeds expectations in terms of durability and aesthetics.

How does PUR binding influence the aesthetics of a book?

PUR binding contributes to the aesthetics of a book with its clean and precise edges. The flexibility of PUR-bound books allows for better lay-flat characteristics, enhancing the overall visual experience. Publishers and designers can leverage the aesthetics of this binding to create books with a professional and polished appearance.

How do I choose between PUR binding and other binding methods?

Choosing between PUR binding and other binding methods depends on project requirements, book aesthetics, durability, and budget. Consider factors such as the type of project, desired book aesthetics, durability needs, and budget constraints when making a decision.

What are the advantages of PUR binding in modern book publishing?

PUR binding offers durability, flexibility, and high-quality binding capabilities. It creates a strong and durable bond that can withstand frequent use and challenging conditions, making it a preferred choice for modern book publishing.