When it comes to producing booklets, brochures, catalogues, or any other bound printed materials, selecting the binding technique is extremely important. One popular and cost-efficient option is saddle stitched booklet printing , which happens to be an MVP Print Speciality.

In this guide we will delve into the concept of saddle stitch booklets, types of stitching suitable for both longer and shorter print runs, its cost-effectiveness, faster turnaround time, and limitations in terms of page count.

What Does Saddle Stitching Entail?

Creating a Saddle Stitch Booklet is a printing process method for binding booklets, brochures, and other multi-page printed materials fast and effectively. This process involves folding sheets of paper in half and stapling them together along the folded crease or “saddle” of the pages. By using this technique you can achieve a professional-looking booklet that opens flat—a solution for documents with a moderate number of pages.

The Process of Saddle Stitched Booklet Binding

The saddle stitching process is straightforward and budget-friendly—making it an excellent fast and cost-effective choice for printing projects. Here’s how it works after printing booklets :

Collation: The sheets of paper are printed and arranged in the order.

Folding: Next the sheets are folded in half creating the pages of the booklet.

Stapling: Then a row of staples is inserted through the folded crease to securely hold the pages together.

Trimming: After that, any excess paper is trimmed from the edges to give the booklet a finished appearance.

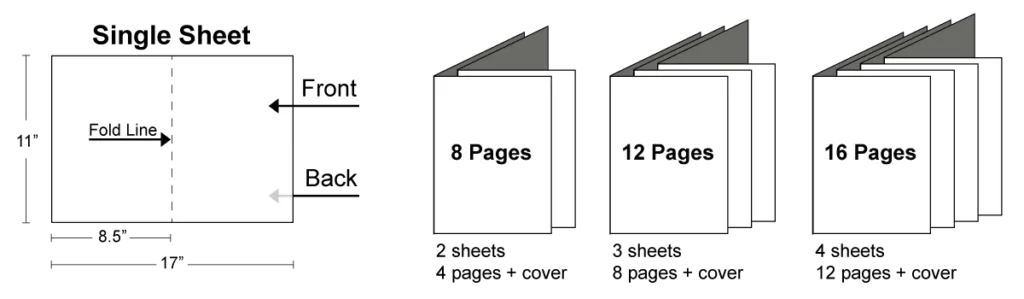

Producing a Saddle Stitch Booklet is predominately an option for booklets with 8 to 76 pages making it suitable for a range of applications.

Different Stitching Methods for Longer vs. Shorter Print Runs

When considering saddle stitching it’s important to know that stitching methods depend on the length of your print run.

Saddle Stitching for Shorter Print Runs

For print runs under 500 booklets, a standard saddle stitching approach works well. It is cost effective and efficient making it ideal for businesses, event promotions and marketing campaigns. The setup time required for shorter print runs is minimal (Known as Hand Fed Stitching) so you can get your booklets produced quickly and affordably.

Saddle Stitching for Longer Print Runs

If you have a print run in the thousands or more you might consider high-speed saddle stitching. This automated process uses wire staples (spooled) machinery to bind booklets

While the initial setup, for high-speed saddle stitching, may require time and money it becomes increasingly cost-effective as the print run size grows larger. This makes it a practical choice for materials, product catalogues, and extensive publications. Generally, the choice for an Offset Print run is printed in sections (instead of a digitally printed collated book)

The Cost Effectiveness of Saddle Stitching Compared to Book Printing Methods

Saddle stitching offers economical advantages over alternative bookbinding techniques, particularly for booklets, brochures, and similar materials. Here are some key reasons why saddle stitching is a budget option;

Minimal Use of Materials

Saddle stitching utilizes binding materials by relying on staples and a simple folding process. This reduces production costs making it affordable for both long and short print runs.

Low Setup Expenses

The setup process for saddle stitching is relatively straightforward for shorter print runs. Consequently this results in setup costs that enable small businesses to afford professionally produced booklets.

Scalability

As mentioned earlier saddle stitching can be adapted to accommodate both short and large print runs. This scalability allows for cost control based on project size ensuring that you only pay for necessary expenses.

Versatility

Saddle stitching offers versatility. Can be used for a range of projects, including event programs, product catalogues, instruction manuals, and marketing brochures. This flexibility allows businesses to utilize the cost method across various types of printed materials.

Faster Turnaround with Saddle Stitched Booklets

One of the benefits of opting for saddle-stitched booklets from MVP Print is the super fast turnaround time. Whether you need booklets for a last-minute trade show, an event, or a promotional campaign, saddle stitch is the quickest binding option (particularly for booklets that have a self-cover) so that you receive your materials promptly.

Same-Day or Next-Day Printing

With MVP Prints‘ dedication to production, it’s often possible to have your saddle-stitched booklets ready within just one day. This proves advantageous when you require marketing materials or event programs super quick

Short Production Time

Saddle stitching is a process that completes the production quickly—collating, folding, stapling and trimming are all done in a short span. As a result for print runs there’s no need to wait weeks before receiving your booklets.

Meeting Deadlines

The ability to produce saddle-stitched booklets quickly enables businesses to meet deadlines, which is essential, for promotional events product launches, and other time-sensitive initiatives. Other Binding methods (eg Wire, Coil, or Perfect Binding) have longer setups, and in Perfect Bindings case, drying time.

Limitations of Saddle Stitching in Terms of Page Count

While saddle stitching is an option for projects it does have limitations when it comes to the number of pages a booklet can hold. Typically saddle stitched booklets work best for Saddle Stitch Booklet that have a page count (or booklet size) between 8 and 76 pages.

Considering the Number of Pages

The main drawback of saddle stitching is the thickness of the booklet. As the page count increases so does the thickness of the booklet. This can make it difficult to keep the pages flat when opened (called ‘bounce’) leading to readability and handling challenges, and increased wear and tear on the binding.

Other Binding Methods to Consider

If you are looking to print booklets with higher page counts or ones that require a substantial appearance, alternative binding methods like Perfect Binding (PUR), Coil or wire o binding may be more suitable. These methods offer advantages such as accommodating booklets with a larger amount of printed pages – without compromising readability and durability.

It’s also important to remember that true `Hard Cover’ books aren’t an option. Why? Because the staples won’t penetrate the dense cover, don’t look too hard for Hard Cover options when it comes to a Saddle Stitch booklet!

Always remember as well that your saddle stitch booklets need to have your pages in multiples of 4pp to make the binding work. Some clients will add blank pages on the inside covers (the outside has its cover printed, the inside is blank) to add extras to their book to make them in a multiple of 4.

To sum up, saddle stitching is a versatile choice for creating booklets, brochures, and similar printed materials quickly, cost-effectively, on an extensive range of books with under 70 (ish) printed pages

Whether you need to print a short batch or a larger project, MVP Print’s saddle stitching services provide a high-quality solution with quick turnaround times. However, it’s important to keep in mind the constraints related to the number of pages and explore binding options for booklets. that have higher page counts.

In the end, saddle stitching remains a perfect choice that can cater to the requirements of businesses and organizations in all sectors.

For items such as Exhibition Catalogues, Event Booklets, Research Material, Policy Documentation, School Diaries, and many other bound booklet types – it’s the most common and popular form of commercial binding there is.