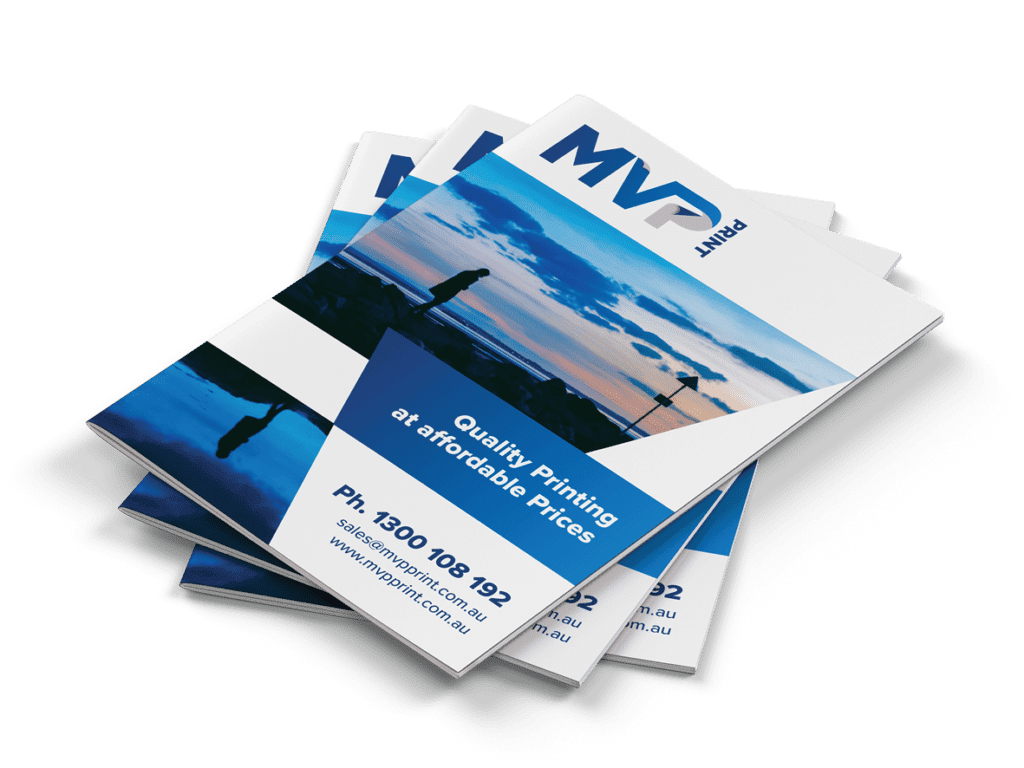

Saddle stitching is a well-liked bookbinding technique that folds and staples paper together. It’s a budget-friendly and flexible choice for printing needs. At MVP Print, we’re experts in saddle stitching, offering top-notch saddle stitched booklets and books for various uses. We provide an extensive range of paper options for saddle stitched booklets to meet your specific project needs. If you’re curious about what a saddle stitched book is, it’s a book bound using this efficient method. It’s perfect for small booklets, magazines, catalogues, and other documents with fewer pages.

Saddle stitching is commonly used for books with fewer pages. It provides fast production times and doesn’t increase a book’s weight or size. This keeps mailing and shipping costs low. With saddle stitching, you can create books in different sizes and orientations, like portrait, landscape, or square. It’s ideal for both professional-looking books and cost-effective printing solutions. MVP Print is ready to help you create your ideal saddle stitched book.

What is a Saddle Stitched Book ? Understanding Saddle Stitched Binding

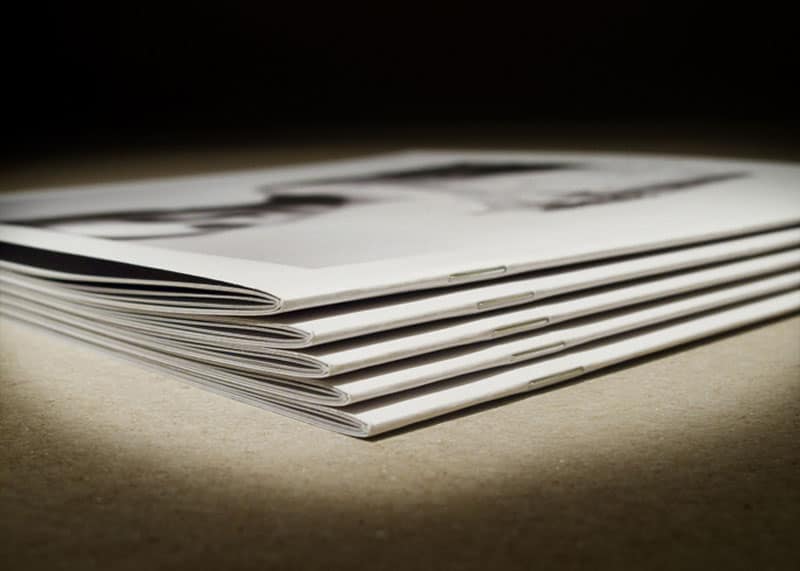

Saddle stitched binding is a common method used to create bound books. It involves folding and stapling folded sheets of paper together. This method is simple yet effective, making it ideal for small to medium-sized projects. The term “saddle stitching” comes from the way the paper is draped over a saddle-like device during stapling.

The process of saddle stitching involves folding the paper in half and stapling along the fold. This creates a strong bond that can handle heavy use. Machines are used to fold and staple the paper, making high-quality bindings quickly and efficiently.

The Basic Concept of Saddle Stitching

Saddle stitching is a cost-effective way to bind small to medium-sized projects. It offers significant savings compared to other methods. For saddle stitched booklets, the page count for saddle must be divisible by 4 to ensure structural integrity. This method allows booklets and brochures to open flat, making them easier to read and reference.

How the Binding Process Works

The saddle stitching production process includes collating, folding, stapling, and trimming pages together. Aligning and organizing printed pages is crucial to ensure a professional appearance. This quick process reduces the wait time, unlike other binding methods. Dedicated machines increase efficiency by automating folding, collation, and stapling for larger projects.

Why It’s Called Saddle Stitching

The name “saddle stitching” comes from the use of a saddle-like apparatus during stapling. It’s suitable for projects with page counts from 4 to 144, following the “rule of four.” Saddle stitched binding is popular for marketing materials and educational guides. However, the recommended maximum page count can vary among printers due to factors such as sheet thickness and binding equipment used.

Designing a Saddle Stitched Booklet

Creating a saddle stitched booklet involves careful planning and attention to detail. From setting up margins and bleed to selecting the right paper thickness, each step plays a crucial role in the final product’s quality and appearance. Here’s what you need to know to design a professional-looking saddle stitched booklet.

Setting Up Margins and Bleed

When designing a saddle stitched booklet, setting up margins and bleed correctly is essential to ensure a polished and professional finish. Margins are the spaces between the edge of the page and the content, while bleed refers to the area where the content extends beyond the trim edge. Properly setting up these elements helps prevent any unwanted white edges or cut-off content. Here are some key steps to follow:

- Internal Bleed: Leave a minimum of 5mm internal bleed for all saddle stitched booklets and magazines. This ensures that any images or background colors extend beyond the trim edge, preventing any white lines from appearing after trimming.

- Margins: Ensure that the margins are sufficient to accommodate trimming variations. This helps maintain a consistent and professional look throughout the booklet.

- Extend Content: Extend images or background colors beyond the trim edge to ensure proper trimming. This is crucial for achieving a seamless and professional appearance.

- Consult Guidelines: Always consult your printing provider for specific measurements and guidelines. Different printers may have varying requirements, so it’s important to follow their recommendations.

By carefully setting up margins and bleed, you can ensure that your saddle stitched booklet looks professional and polished.

The Technical Process Behind Saddle Stitching

The saddle stitching process involves several steps, requiring specific bookbinding equipment and printing software. It folds and staples paper sheets together, resulting in a professional booklet. The collective fold lines of the cover and interior pages are critical for binding the book together securely while allowing for free movement of the pages.

Key equipment includes machines for folding and stapling paper efficiently. The software handles page design, layout, and binding machine control.

Here are the main steps in the saddle stitching process:

- Folding: Sheets of paper are folded in half to form book pages.

- Stapling: Pages are stapled along the fold line with wire staples.

- Trimming: The book’s edges are trimmed for a clean finish.

MVP Print uses advanced equipment and software for quick, high-quality booklet production. Their streamlined process and quality checks ensure every booklet meets top standards.

Page Count and Paper Considerations

When considering saddle stitching, page count and paper selection are paramount. The maximum page count for this method is 64 pages, but size and paper type can alter this. It’s also crucial to remember that the minimum page count is 8 pages, with each sheet contributing to 4 pages.

To maintain correct page order and facilitate proper folding during the saddle stitching process, it is important to add blank pages. This helps create a consistent layout, especially when dealing with an odd number of pages or specific content arrangements.

Paper weight and thickness significantly impact the book’s durability and look. Thicker paper may require a lower page count to maintain a professional appearance. Paper weights for saddle stitched books vary, with lightweight at 70-100 GSM, standard at 100-120 GSM, and heavyweight at 120-200 GSM.

Paper Options

- Lightweight paper (70-100 GSM): ideal for brochures and informational booklets

- Standard paper (100-120 GSM): suitable for a wide range of booklets

- Heavyweight paper (120-200 GSM): provides a premium feel and improved durability

- Cover stock (above 200 GSM): perfect for cover printed projects

Choosing the right cover stock is also vital, as it influences the book’s appearance and durability. Heavier paper stocks offer a more luxurious look compared to lighter ones. By carefully selecting these factors, you can ensure your saddle stitched booklets are of superior quality and meet your printing requirements.

A self cover option, where the same paper stock is used for both the cover and inner pages, can offer cost savings and a cohesive design. This contrasts with cover printed projects that use different paper stocks for a more distinctive appearance.

| Paper Type | GSM Range | Description |

|---|---|---|

| Lightweight | 70-100 | Ideal for brochures and informational booklets |

| Standard | 100-120 | Suitable for a wide range of booklets |

| Heavyweight | 120-200 | Provides a premium feel and improved durability |

| Cover Stock | Above 200 | Perfect for cover printed projects |

Importance of Paper Thickness and Quality

The paper thickness and quality you choose for your saddle stitched booklet significantly impact its overall look and feel. Thicker paper stock provides a more substantial and high-end appearance, while thinner paper stock may appear flimsy and less durable. Here are some factors to consider when selecting paper stock:

- Overall Look and Feel: Paper thickness affects the overall look and feel of your booklet. Thicker paper stock provides a more substantial and high-end appearance, making your booklet feel more premium.

- Durability: The quality of the paper directly impacts how well it withstands wear and tear. Higher quality paper is more durable and can better handle frequent handling.

- Suitability: Choose a paper stock that is suitable for the content and purpose of your booklet. For example, a lightweight paper may be ideal for informational brochures, while a heavyweight paper might be better for a high-end catalogue.

- Consistency: Ensure that the inner pages and cover are printed on the same paper stock or complementary stocks to maintain a cohesive look.

By carefully selecting the right paper thickness and quality, you can enhance the overall appearance and durability of your saddle stitched booklet.

Benefits of Choosing Saddle Stitched Books

Saddle stitching is a cost-effective method, ideal for booklets, catalogs, and other printed materials. It allows businesses to create high-quality books without straining their budget. This makes it a preferred choice for many.

The saddle stitch binding method offers a quick turnaround time and maintains a low weight, making it an efficient choice for various projects. The method boasts a professional appearance, thanks to the use of discreet staples. This feature is perfect for businesses aiming to present a polished image. Saddle stitched books are also durable, ideal for businesses needing to produce large quantities.

The benefits of saddle stitching can be summarized as follows:

- Cost-effective, making it suitable for businesses with limited budgets

- Professional appearance, thanks to the discreet staples used in the binding process

- Durable, able to withstand heavy use and handling

- Quick turnaround time, making it ideal for urgent projects

In conclusion, saddle stitching is a top choice for businesses aiming to produce quality books without sacrificing cost or durability. Its numerous benefits make it a staple in the printing industry.

| Binding Method | Cost-Effectiveness | Professional Appearance | Durability |

|---|---|---|---|

| Saddle Stitching | High | High | High |

| Perfect Binding | Medium | High | High |

Common Applications and Uses

Saddle stitched books are widely used for various purposes, including magazines, catalogues, event programs, and brochures. These common applications take advantage of the binding method’s durability and professional appearance.

A saddle stitch booklet is created from folded sheets of paper stapled along the fold, making it an economical choice. The page count and binding methods are crucial for ensuring a clean and organized appearance.

Magazines and Catalogues

Magazines and catalogs are two of the most common applications for saddle stitching. Maintaining the correct order and pairing of each printed page is crucial for these publications. They require a high-quality and durable binding that can withstand heavy use. Saddle stitching is ideal for these types of publications, as it provides a professional-looking finish and can be produced quickly and efficiently.

Event Programs and Brochures

Event programs and brochures are also common applications for saddle stitching. Blank pages are crucial in maintaining proper page order and layout, ensuring that each printed page is correctly paired and avoiding misalignment in the document’s sections. They require a professional-looking binding that can be produced quickly and efficiently. Saddle stitching is suitable for these types of materials, as it provides a durable and attractive finish.

Marketing Materials

Marketing materials, such as flyers and pamphlets, are also commonly used with saddle stitching. Saddle stitch booklets are created by folding sheets in half and stapling them along the fold, making it crucial to select the right paper stock to ensure professional quality and durability. These materials require a professional-looking finish and can be produced quickly and efficiently using the saddle stitching method.

Some common applications of saddle stitched books include:

- Magazines

- Catalogues

- Event programs

- Brochures

- Marketing materials

These common applications take advantage of the durability and professional appearance of saddle stitched books, making them a popular choice for businesses and organizations.

| Application | Description |

|---|---|

| Magazines | High-quality and durable binding for heavy use |

| Catalogues | Professional-looking finish for product showcases |

| Event Programs | Quick and efficient production for time-sensitive events |

| Brochures | Attractive and durable finish for promotional materials |

| Marketing Materials | Professional-looking finish for flyers and pamphlets |

Finishing Touches

The final steps in the saddle stitching process are crucial for achieving a polished and professional look. Trimming and cutting are essential to ensure clean edges and uniform dimensions, giving your booklet a finished appearance.

Trimming and Cutting

Trimming and cutting are the final steps in the saddle stitching process that give your booklet a polished and professional look. To achieve clean edges and uniform dimensions, follow these steps:

- Use Proper Tools: Use a paper cutter or a cutting tool with a straight edge to achieve clean and uniform edges. This ensures that all pages are trimmed evenly.

- Follow Measurements: Follow the proper measurements to ensure consistent dimensions. This helps maintain a professional appearance and prevents any pages from being cut too short or too long.

- Align Trim Edge: Ensure that the trim edge is aligned with the fold line to prevent uneven edges. Proper alignment is crucial for a clean and professional finish.

- Trimming Tool: Use a trimming tool or a guillotine to trim the booklet to the desired size. This ensures that all edges are clean and uniform, giving your booklet a polished look.

By paying attention to these finishing touches, you can ensure that your saddle stitched booklet looks professional and well-crafted.

MVP Print’s Professional Saddle Stitching Services

MVP Print provides a variety of professional saddle stitching services for businesses across Australia. Our binding process employs specialized equipment and software to fold and staple paper sheets together. This ensures a superior finish. We focus on quality assurance, ensuring every book meets our high standards. Our saddle stitch binding process is both efficient and of high quality, making it ideal for documents with lower page counts.

We understand the value of customization at MVP Print. We offer a range of options, including paper weights, finishes, and sizes. Our team supports customers from design to production, ensuring satisfaction and quality. We use advanced printing equipment and premium materials for high-quality output.

Our Binding Process

Our binding process accommodates various page counts, from small booklets to large publications. We leverage advanced printing technology for quick delivery and meeting deadlines. The saddle stitch binding method we use is particularly advantageous for its quick turnaround time and ability to maintain a low weight, making it ideal for both low and higher page counts. MVP Print is known for fast turnaround times, making us perfect for urgent printing needs.

Quality Assurance Standards

We maintain high-quality assurance standards to ensure every book meets our expectations. Our team reviews every step of the printing process to guarantee excellent results. MVP Print is committed to providing top-notch saddle stitch binding, ensuring a professional appearance for lower-page-count documents. We also offer eco-friendly printing solutions, combining sustainability with quality.

Available Options and Customisation

At MVP Print, we offer a wide range of customization options to meet your needs. These include:

We provide an extensive range of paper options to ensure your project is tailored to your specific requirements.

- Different paper types and weights

- Various finishes, such as matte or gloss

- Custom sizes to fit your unique requirements

- Page counts ranging from small to large

| Service | Description | Benefits |

|---|---|---|

| Professional Saddle Stitching | High-quality binding process | Fast turnaround times, high-quality finish |

| Customization Options | Range of choices for paper, finish, and size | Tailored to meet specific business needs |

| Quality Assurance | High standards for every aspect of printing | Guaranteed quality, eco-friendly solutions |

Comparing Saddle Stitching to Other Binding Methods

Saddle stitching is a well-liked binding method, but it’s not the only one. Examining different binding techniques can guide you in selecting the most suitable for your project. Saddle stitching is frequently compared to perfect binding and wire binding. Each has its own set of benefits and drawbacks.

Saddle stitch booklets are particularly advantageous due to their cost-effectiveness and versatility, making them ideal for various printing projects. They involve folding sheets in half and stapling them to create a streamlined booklet, which ensures professional quality and durability.

Saddle stitching is known for being cost-effective and adaptable, producing quality books swiftly and efficiently. Yet, it’s restricted to page counts divisible by four. Perfect binding, which involves gluing pages together, is preferred for thicker books. Wire binding, which uses a wire to hold pages together, is ideal for books that need frequent updates.

- Saddle stitching is suitable for booklets containing up to 64 pages, with larger publications having a maximum of 48 pages to prevent staples from popping out.

- Perfect binding is ideal for publications with over 96 pages and is commonly used for softcover options like books, magazines, and manuals.

- Wire binding allows pages to turn a full 360 degrees, making it advantageous for materials requiring hands-free reading.

In terms of cost, saddle stitching is generally the most economical option. Perfect binding and wire binding, while more expensive, offer unique benefits. The choice of binding method hinges on your project’s specific needs, including page count, paper weight, and desired durability.

What is a Saddle Stitched Book ? A Summary.

The choice of binding method for your printed materials hinges on your project’s specific needs. Saddle stitching stands out as a cost-effective and versatile option. It’s ideal for a broad spectrum of uses, from magazines and catalogues to event programs and marketing materials. Its efficiency and user-friendly nature make it a top choice for many printing needs. Saddle stitch binding is particularly versatile and cost-effective, making it suitable for various low-page count documents.

When weighing your binding options, consider page count, paper weight, and intended use. Saddle stitching is best for publications with 8 to 76 pages. It ensures the material remains flat and easy to read. For larger projects, perfect binding might be more suitable.

Choosing the right binding method is crucial. It depends on your specific requirements and preferences. By understanding the benefits and considerations of each method, you can make an informed decision. This will result in professional-looking, durable, and engaging printed materials that meet your business or organization’s needs.